Effective Ways to Measure a Box: Smart Techniques for Accurate Results in 2025

Measuring a box accurately is essential for a variety of purposes, including shipping, storage, and overall planning. Understanding how to measure a box not only helps in ensuring you select the right size but also saves on costs and space. This comprehensive guide will provide you with smart techniques and practical tips for measuring box dimensions, from length and width to height. In 2025, employing accurate box measurement techniques will become even more relevant as shipping needs continue to evolve.

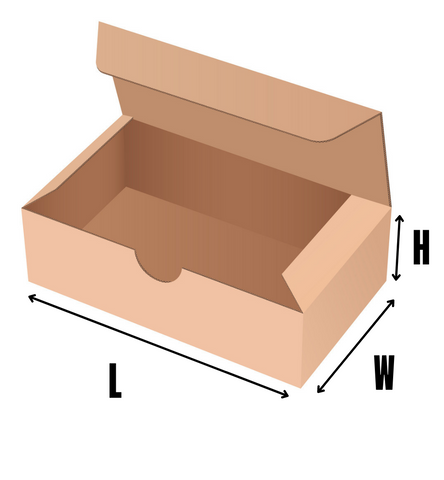

Understanding Box Dimensions

Every box has three primary dimensions: length, width, and height. Understanding these dimensions is crucial for **accurate box measurements**. The **measuring box length** entails identifying the longest side of the box. It’s important to note that the length is measured parallel to the top flap when a box is in a standing position. Conversely, the **measuring box width** is the side perpendicular to the length. Measurement accuracy is key to optimizing **box size calculations**, especially when determining volume for shipping needs, contributing to both cost efficiency and space optimization.

Measuring Length, Width, and Height

To achieve precision when **measuring box length, width, and height**, use a measuring tape, which is one of the best tools for this job. Begin by laying the box flat on a stable surface. From there, pull out the measuring tape to measure from one end of the box to the other for the length. Repeat this for the width. Finally, to determine the height, measure from the bottom to the top of the box. Keep in mind to measure in straight lines, avoiding any curves that might yield false dimensions. Maintaining this approach ensures that you obtain **accurate box measurements** for further uses.

Tools for Box Measurement

Utilizing the right **box measuring tools** is crucial for attaining reliable measurements. Commonly used tools include a metal measuring tape, a ruler, or a caliper for more intricate measurements. The choice of tools largely depends on the box size and dimensions you are measuring. For large boxes, a measuring tape would be ideal, while smaller, more precise measurements might require a caliper. Regularly checking your tools for accuracy is essential; miscalibrated tools could lead to incorrect **box measurement standards**, ultimately affecting your preparation for shipping or storage solutions.

Box Measurement Techniques

Employing effective box measurement techniques becomes a necessity, especially for those working within logistics or shipping industries. To measure boxes accurately, it’s essential to understand various measurements appropriate for different scenarios—be it for shipping purposes or for optimizing storage solutions. Consider the application of measuring irregular boxes or cylindrical boxes where traditional measurements may not suffice. This knowledge plays a vital role in ensuring that your box measurements are precise and aligned with industry standards.

Measuring Irregular Boxes

When it comes to **measuring irregular boxes**, it’s important to address each section separately. Begin by determining the box’s maximum length, width, and height as before. Utilize measuring tape around the widest areas, keeping an eye out for any protrusions or unusual shapes that might add complexity to your measurements. For irregularly shaped boxes, it may also be beneficial to sketch a quick diagram and note down the measurements to convey them more effectively when selecting proper packing materials.

Best Practices for Measuring Boxes for Shipping

In shipping, the accuracy of **box measurements** can directly impact delivery times and costs. To ensure you meet shipping requirements, always double-check your dimensions and adhere to the shipment guidelines outlined by your chosen carrier. A common practice is to weigh and measure after sealing the package to ensure no unexpected changes occur. For effective strategies, consider using a **box measurement checklist** that aligns with your shipping processes. This checklist should include dimensions for weight restrictions, volume allowances, and any packaging guidelines from carriers like UPS or FedEx.

Calculating Box Volume and Size Specifications

After comprehending the box dimensions, the next critical step is calculating the box volume. Box volume is vital for optimizing space—not just in storage, but also for shipping calculations. To determine the **box volume**, multiply length by width and then by height. This straightforward equation results in cubic measurements that are essential for any shipping processes. Additionally, being aware of **standard box sizes** can simplify the selection process, allowing you to match products effectively with the ideal box dimensions.

Understanding Box Size Calculations

Besides calculating the volume, you may need to consider different size specifications based on the nature of what you’re packing. For instance, **measuring box for moving** can involve applying these box calculations in determining how many boxes you’ll require for your items. This foresight helps you price out your moving costs and decide whether you need specialized boxes for valuable items, ensuring that all **box sizing** needs are met. Always refer to box size charts provided by storage or moving companies to assist you in this process.

Box Measurement Standards

When dealing with logistics and shipping, understanding **box measurement standards** is paramount. Most FedEx or UPS carriers expect shippers to adhere to certain protocols when measuring boxes, including weight limitations and size restrictions. These standards may vary globally, so it is essential to be familiar with the preferred measurement methodologies within your region and industry. Adhering to these standards can significantly influence shipping success and avoid additional costs or delays.

Tips for Effective Box Measurement

To maximize the effectiveness of your box measurement process, here are several essential **box measurement tips**. Begin with tracking your measurements consistently to avoid errors. Also, utilize tools designed for measurement efficiency. Always take multiple readings and average them to ensure accuracy; this can minimize errors linked to tool misalignment or movement during measuring. If measuring requires you to measure live objects, like furniture, get help from a partner to hold the tape firmly in place.

Measuring Boxes for Storage Solutions

When **measuring box for storage**, consider the orientation of the boxes—how they will stack, fit, and optimize your available space. Measure not only the boxes but also the areas where they will be stored. Assess entrance dimensions and clearance for movement. In larger storage facilities, optimized layout planning considering your box dimensions plays a vital role in efficient storage solutions.

Common Mistakes in Box Measurement

Familiarizing yourself with common mistakes in measuring boxes is imperative in achieving accurate results. One frequent error includes neglecting to measure the **depth of a box**, relying solely on length and width—or not taking note of the exact orientation for length and width measuring. Ensuring you account for all dimensions, and rectifying common errors associated with user-perception biases, can greatly enhance measurement accuracy. Adequate preparation and utilizing correct techniques will lead you to become proficient in measuring boxes timely and effectively.

By now, you have an intricate understanding of how to measure a box and the algorithms behind adequate calculations necessary for certain applications. Use these adjustments in your technique, make sure to factor in regular best practices, and actively engage with industry standards for all box-related endeavors you’ve encountered.

Key Takeaways

- Mastering box dimensions requires an understanding of length, width, and height calculations.

- Using correct **box measuring tools** improves accuracy for both standard and irregularly shaped boxes.

- Adhering to measurement standards is essential for shipping and logistics efficiency.

- A checklist fosters meticulous measurements and saves potential costs.

- Awareness of common pitfalls enhances the precision of your box measurements.

FAQ

1. What tools can help in how to measure the inside of a box?

To get measurements for the inside of a box, utilize a flexible measuring tape for depth and internal corners. It’s best to ensure the tape measures the length as well as width inside accurately. Additionally, a caliper can be advantageous for tighter spaces, ensuring you get the most precise measurement possible.

2. How can I measure a box for shipping?

When preparing **measuring box for shipping**, always measure length, width, and height first using a measuring tape. Check any recommended size standards from the shipping company. It’s equally important to weigh the box after packing, as some companies impose weight restrictions, crucial in maintaining shipping compliance.

3. What are some best practices for measuring box dimensions?

An effective practice includes taking multiple measurements for verification and recording results for future reference. Confirm all sides, dimensions, and diagonals balance against packing needs. Creating a checklist can ensure no crucial aspect is missed and all standards are met prior to shipping or moving preparations.

4. How do I measure dimensions of a box that is not perfectly rectangular?

For **measuring irregular boxes**, methodically assess each section by measuring collaterally and identifying the longest and widest points. Keep records of multiple measurements and use them creatively to adapt packing strategies suited for the specific cargo—doing so ensures that the best packing techniques are employed.

5. Are there specific measurement standards for box sizes in shipping?

Yes, **box measurement standards** can significantly vary based on shipping company policies and international regulations. Always refer to the guidelines of carriers like UPS or FedEx to ensure measurement compliance, mitigating extra costs or delivery issues linked to size discrepancies.

6. What should I know about measuring box depth?

When **measuring depth of a box**, ensure you measure from the bottom to the top, much like height. This is crucial for boxes designed to hold items for storage or shipment, as depth measurements can often alter how products are packed or how they will fit within shipping arrangements.

7. How can I calculate box volume accurately?

To calculate the **box volume**, apply the formula that multiplies length, width, and height together. It helps in working from the outer dimensions primarily and is essential in estimating whether your box will fit the items you need while conforming to packing standards mandated for shipping.